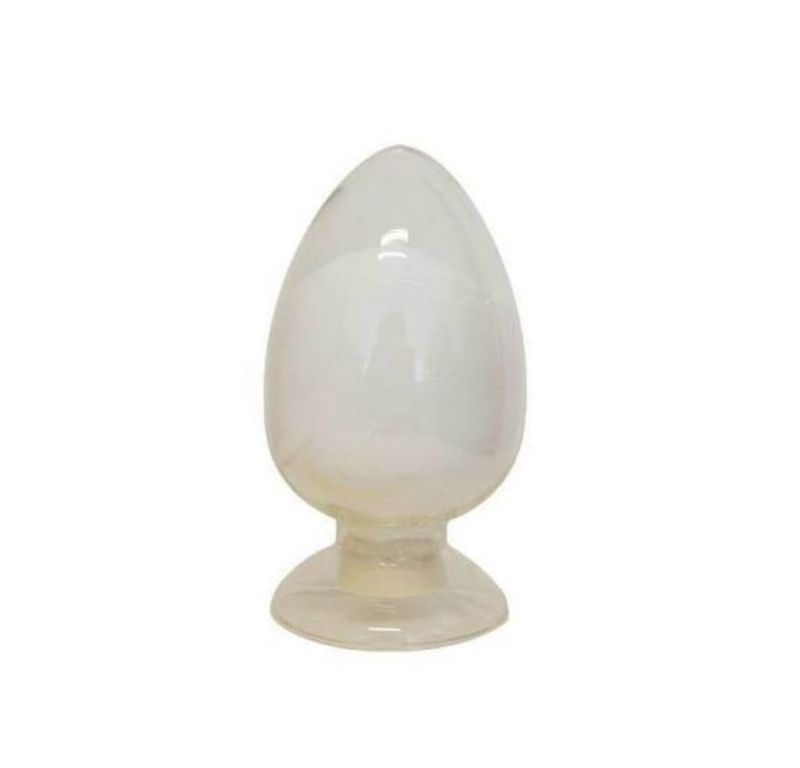

The use of PVC foaming regulator:

The foaming of PVC material is to make the molecular distribution of PVC more uniform. Make the quality of PVC products more objective. The PVC sheet foamed by PVC foaming regulator has a very good independent structure. Sometimes, while using PVC foaming regulator, we also use some foaming accelerators. Foaming accelerators include metal oxides such as zinc oxide and lead oxide, organic acid salts such as zinc stearate, and urea derivatives.

Advantages of PVC foaming regulator:

PVC foaming regulator has all the characteristics of PVC processing aids, with a molecular weight higher than that of PVC processing aids. Adding an appropriate amount of PVC foaming regulator during the processing of PVC products can improve the strength of the melt and prevent the fu sion of bubbles. At the same time, it can also have a good plasticizing effect. The purpose is to ensure that the melt has good fluidity.

sion of bubbles. At the same time, it can also have a good plasticizing effect. The purpose is to ensure that the melt has good fluidity.

Precautions for the use of PVC foaming regulator:

When using PVC foam modifiers, it is important to pay attention to PVC products with different degrees of polymerization and choose different foam modifiers. Plastic foam products include foam boards, foam thick boards, foam thin boards, wood plastic foam boards, lead plastic foam boards, etc. As PVC foam additives are also acrylic substances with processing aid properties, attention should be paid to the internal and external lubrication balance of the formula when using them.

Key points of PVC foaming process control:

Plastic foam molding is divided into three processes: formation of bubble core, expansion of bubble core, and solidification of foam body. For PVC foam sheets with added chemical foaming agents, the expansion of bubble nuclei has a decisive impact on the quality of the foam sheet. PVC belongs to straight chain molecules with short molecular chains and low melt strength. During the process of bubble core expansion into bubbles, the melt is not enough to cover the bubbles, and the gas is prone to overflow and merge into large bubbles, reducing the product quality of foam sheets.

Post time: Nov-02-2024