Heat stabilizer: Plastic processing and shaping will undergo heating treatment, and during the heating process, the plastic is inevitably prone to unstable performance. Adding heat stabilizers is to stabilize the performance of PVC materials during heating.

Improved processing aids: As the name suggests, the so-called improved processing aids are designed to improve some properties of PVC during processing, including improving the poor flowability of PVC, which is prone to sticking to equipment and coking. Therefore, a certain amount of processing aids need to be added in the production of plastic profiles to overcome the defects of the plastic profiles themselves.

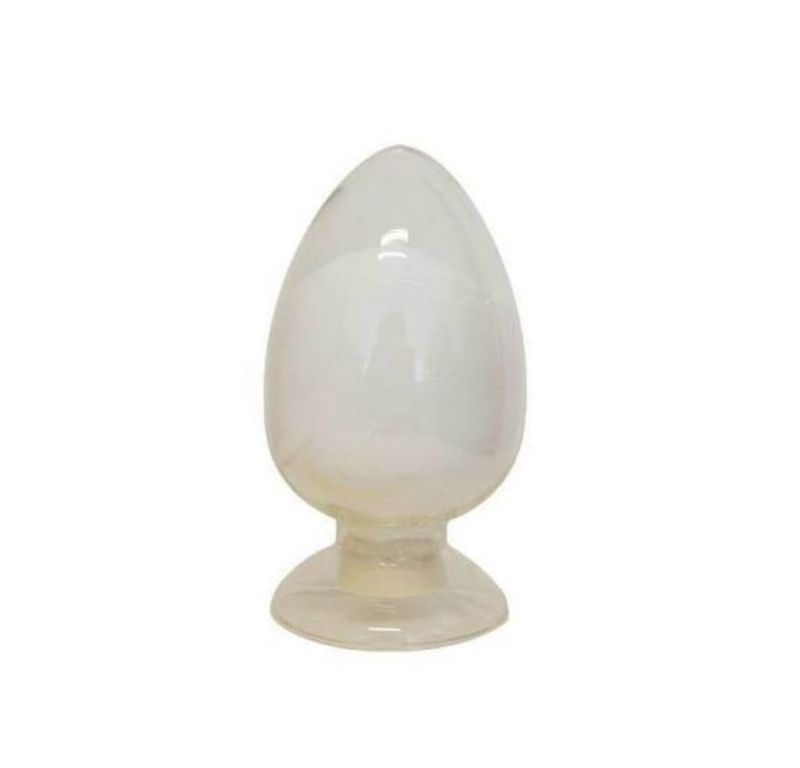

Fillers: Fillers are solid additives that differ in composition and structure from plastics, also known as fillers. It has significant effects and economic value in improving certain physical and mechanical properties of plastics and reducing plastic costs. Adding fillers to the production formula of plastic profiles can reduce the rate of size change after heating, improve impact strength, increase rigidity, and also reduce production costs.

Lubricant: The main function of lubricant is to reduce the mutual friction between polymer and processing equipment, as well as between internal molecules of polymer, prevent resin degradation caused by excessive frictional heat, and improve the efficiency of heat stabilizers.

Post time: Sep-20-2024